Building a Robust Power Plant Maintenance Blueprint

To create a robust maintenance blueprint, we need to identify the maintenance philosophy, maintenance types and workflows, create master plans and maintenance schedule matrices. Additionally, finalizing a condition monitoring system and a critical equipment maintenance strategy are essential.

A solid CMMS platform aims to achieve a planned maintenance activity of nearly 98%. Documentation is crucial in any maintenance activity. The ability of CMMS software to retrieve past maintenance history, failure frequency, and repair times offers insights into past equipment performance and identifies areas where changes are necessary to ensure 100% equipment availability.

Moreover, proper safety training, performance tracking with KPI indicators, a strong audit and review mechanism, and a continuous improvement loop will aid in establishing robust maintenance practices.

Let’s dive into each of the above in detail.

1. Maintenance Philosophy

The main goal is to ensure maximum availability of the equipment, safe operations, regulatory compliance, and minimized lifecycle costs.

Strategies to Include:

- Preventive Maintenance (PM)

- Condition-Based Maintenance (CBM)

- Reliability-Centered Maintenance (RCM)

- Shutdown/Outage-Based Maintenance

- Risk-Based Maintenance (RBM)

2. Maintenance Types & Workflows

| Type | Focus | Tools/Methods |

|---|---|---|

| Preventive (PM) | Scheduled based on time or usage | Time-based schedules, OEM guidelines |

| Predictive (PdM) | Condition monitoring for early fault detection | Vibration analysis, thermography, oil analysis |

| Corrective (CM) | Repairs after failure or defect detection | Root cause analysis, breakdown response |

| Shutdown | Deep inspections and overhauls during planned outages | Turnaround planning, Gantt-based execution |

3. Maintenance Master Plan

A. Asset Register

Each asset should be tagged with:

- Asset ID

- Location

- OEM

- Service interval

- Criticality rating

B. Maintenance Schedule Matrix

| Equipment | Frequency | Maintenance Type | Tools Used | Responsible Team |

|---|---|---|---|---|

| Boiler | Monthly | Preventive | Borescope, NDT | Mechanical Team |

| Turbine | Quarterly | Predictive | Vibration Analyzer | OEM/CBM Experts |

| Generator | Half-Yearly | Preventive | IR Tester, DGA | Electrical Team |

| Cooling Towers | Monthly | Preventive | Manual, CMMS | Utility Team |

4. Condition Monitoring System (Online & Offline)

Key parameters to monitor:

- Vibration (Turbines, Motors)

- Temperature (Bearings, Transformers)

- Pressure (Boilers, Compressors)

- Oil quality (Turbines, Gears)

- Partial Discharge (Generators)

Tools like SKF/CMS systems, FLIR cameras, SCADA, and IoT sensors are ideal for monitoring.

5. Critical Equipment Strategy

Prioritize:

- Boilers, Turbines, Generators, Transformers, HT Motors, ESPs

Action Plan:

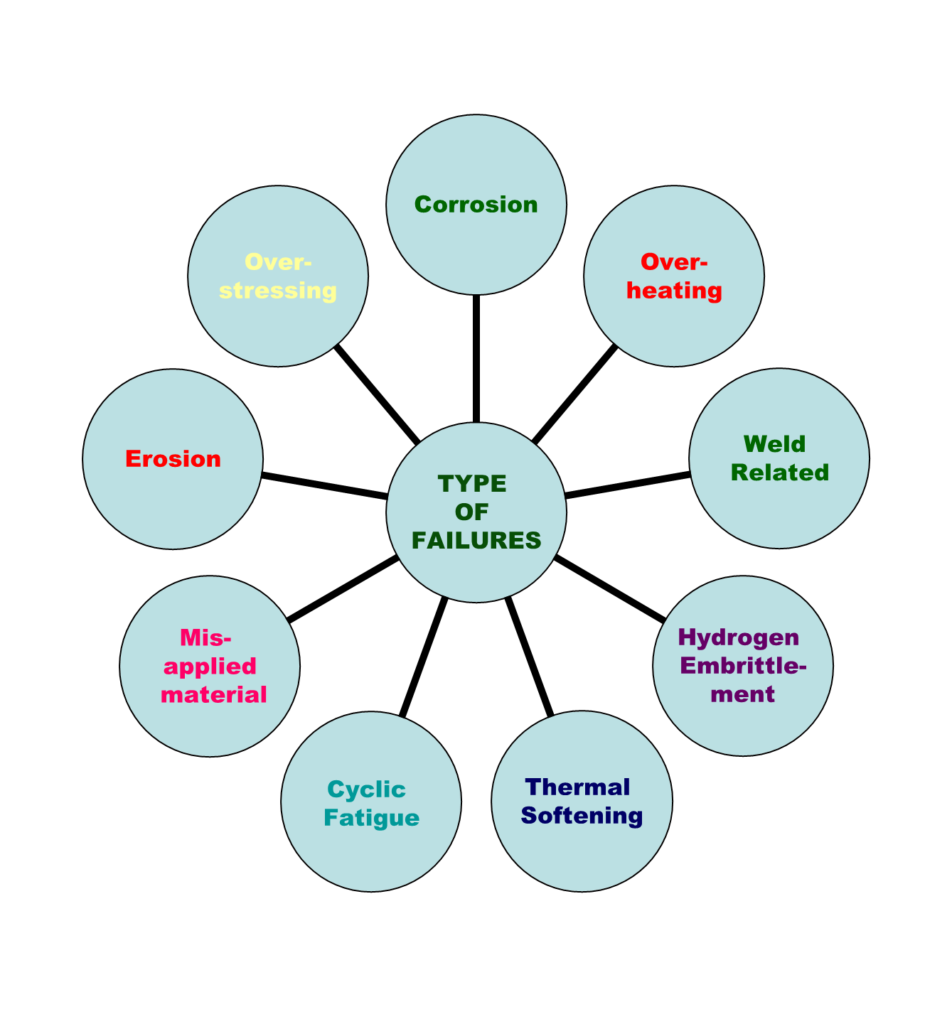

- Develop Failure Mode & Effects Analysis (FMEA)

- Maintain spare parts inventory

- Assign condition-based maintenance triggers

- Establish OEM liaison for critical failures

6. Documentation & CMMS IntegrationUsing a CMMS (like SAP PM, Maximo, or Trons):

- Schedule and log all maintenance activities

- Track KPIs (MTBF, MTTR, downtime, cost/asset)

- Manage spares and inventory

- Trigger auto-notifications for maintenance due

7. Safety, Regulatory & Training

Compliance:

- ISO 55000 (Asset Management)

- ISO 45001 (Occupational Health & Safety)

- Boiler & Factory Act Compliance

Training:

- Standard Operating Procedures (SOPs) and skill matrix for all technicians

- Annual HIRA refreshers

- Mock drills for critical failure scenarios

8. KPIs and Performance Tracking

| Metric | Goal |

|---|---|

| Equipment Availability | > 95% |

| MTTR (Mean Time to Repair) | Reduce year-over-year |

| PM Completion Rate | > 98% |

| PdM Accuracy | > 85% fault prediction |

| Downtime Hours | Target < planned |

9. Audit & Review Mechanism

- Quarterly maintenance reviews

- Yearly third-party health audits

- Digital dashboards for real-time alerts and metrics

- Root Cause Analysis (RCA) after major breakdowns

10. Continuous Improvement Loop

- Capture feedback after every shutdown

- Analyze trends using CMMS data

- Revise maintenance frequency as per performance

- Leverage AI/ML (if feasible) for failure prediction